Jindal-Hissar keeping up the tradition manufactures high quality ERW pipe to be used as Idlers for conveyors. Jindal-Hissar pipes are manufactured using high frequency induction forged welding, imparting a higher strength to the weld portion. In addition to other tests, Drift Expansion test is done to check the Welding of the pipe, it is more stringent than the flattening test as pipe is expanded using a mandrel for the same. The included angle of the mandrel shall be 30°, 45° & 60°, depending on the Customer requirement.

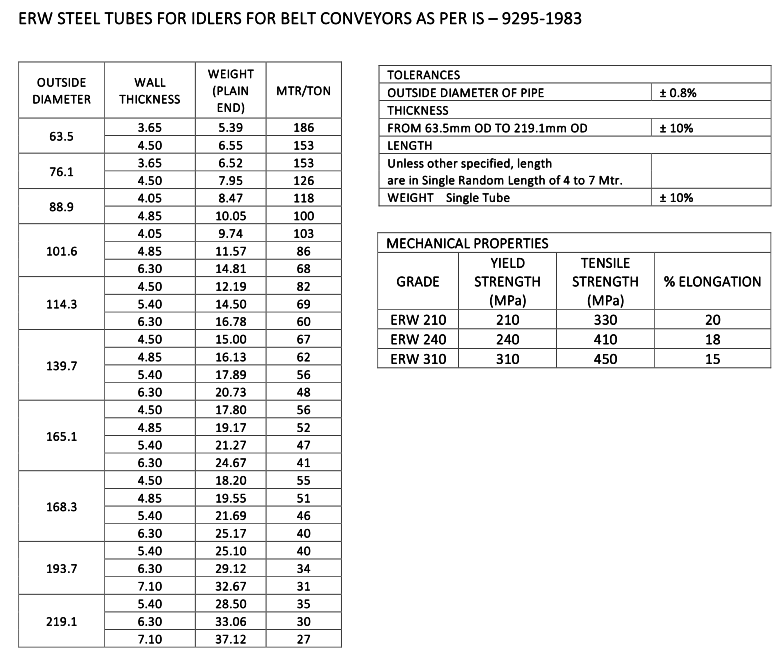

Conveyor rollers standard pipe diameters manufactured by Jindal-Hissar are of the following sizes OD 76mm, 89mm, 101mm, 114mm, 127mm, 139mm, 165mm, 168mm, 193mm, 219 mm of different thicknesses. The ovality of the Pipes is maintained well within the specified limits as defined by Bureau of Indian Standard (BIS) in the specification.

Jindal-Hissar can supply Pipes in all grades of specification, ERW 210, ERW 240 & ERW 310. Grade selection is done for MS black pipe Idlers based on conveyors load handling capacity as conveyed by the customer. Raw material used is of high strength corrosion resistance, durable & sturdy. The raw material used is sourced in from High end manufacturers, JSW, TATA & SAIL are our major suppliers.

Jindal-Hissar manufactures a wide range of MS pipe for Idlers roller to satisfy stringent demands, from handling light weight material to Heavy duty material for conveying various products like sugar, cement, coal, stones, paper, etc.